In industrial environments, even minor issues with machinery can lead to significant operational disruptions. This was the case for a paper mill that experienced frequent bearing failures due to loosening set screws. This seemingly small problem caused major headaches, with up to 10 hours of costly downtime for every incident. Fortunately, Henkel’s LOCTITE® team stepped in to offer a solution that would improve the mill’s operational efficiency and reduce repair time.

The Challenge: Loosening Set Screws

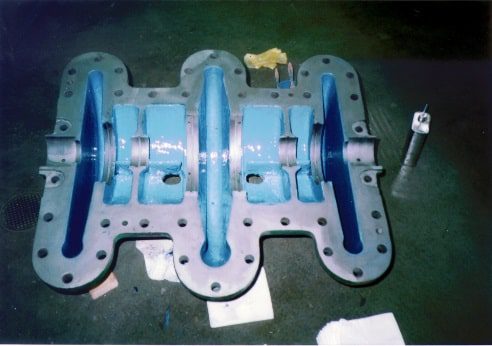

The mill used set screws to secure its roller bearings on shafts, but the screws were prone to loosening over time. This caused the bearings to spin on the shaft, which led to damaged equipment and a cascade of failures. As the bearings continued to fail, the mill faced costly repairs and extended downtime that affected its overall productivity. With up to 10 hours of maintenance required for each incident, this recurring issue was unsustainable.

Henkel’s Solution: LOCTITE® 222™

Henkel’s LOCTITE® team evaluated the situation and recommended LOCTITE® 222™, a powerful threadlocker designed to prevent screws from loosening. Before applying the product, the team ensured the bearing set screws and other components were properly cleaned. Once cleaned, LOCTITE® 222™ was applied, filling the gaps between the bearing, screw, and through-hole. This product works by using metal ions from the set screw to facilitate the curing process, forming a solid, thermoset plastic that locks the components in place.

LOCTITE® 222™ was specifically chosen for its low-strength bonding, which allows for future disassembly without damaging parts—ideal for maintenance needs in industrial environments.

The Results: Reduced Downtime and Improved Equipment Reliability

The results were immediate and impressive. With LOCTITE® 222™ in place, the set screws remained securely fastened, even under high vibration and stress. The paper mill saw a drastic reduction in bearing failures, as the screws no longer loosened over time. As a result, the mill experienced fewer unplanned outages, reducing overall downtime.

The improved reliability of the equipment also helped prevent catastrophic failures, which would have been costly to repair. With reduced bearing failures, the mill was able to maintain a steady production flow, increasing both efficiency and profitability.

In conclusion, Henkel’s LOCTITE® 222™ solution not only addressed the immediate issue of loosening set screws but also helped the mill achieve long-term improvements in equipment performance and operational efficiency. This case demonstrates the importance of selecting the right products for industrial maintenance—solutions that can save time, money, and protect valuable assets from unnecessary wear and tear.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.